Maximizing Cost Savings: Why Cutting Tool Repair is a Smarter Choice Than Buying New

Understanding Cost Savings in Manufacturing

Cost savings is a critical factor in manufacturing and production industries. It refers to reducing expenses while maintaining or improving operational efficiency. When it comes to cutting tools, businesses often face the challenge of whether to repair their existing tools or invest in new ones.

Carbide Tool is unique in helping customers maximize their cutting tool repairs with specialized, high-quality tool repair. By using hard weld to match the pre-existing hardness of the tool and utilizing independent inspectors, CTS has changed the way customers look at cutting tool repairs, and how cost-effective our solutions can be.

How Can Tool Repair Save You Money?

Replacing cutting tools frequently can become a significant expense over time. Repairing tools instead of buying new offers several financial and operational advantages:

- Cost Effective – Repairing a tool is typically 50-80% cheaper than buying a new one.

- Extended Tool Life – Properly maintained and repaired tools can last much longer, delaying the need for costly replacements.

- Consistent Performance – Carbide Tool’s precision guarantee ensures all repaired tools perform just as well as new ones, ensuring production efficiency.

- Reduced Downtime – Ordering new tools can lead to long lead times, whereas repairing existing tools allows for a faster turnaround – with expedite options always available.

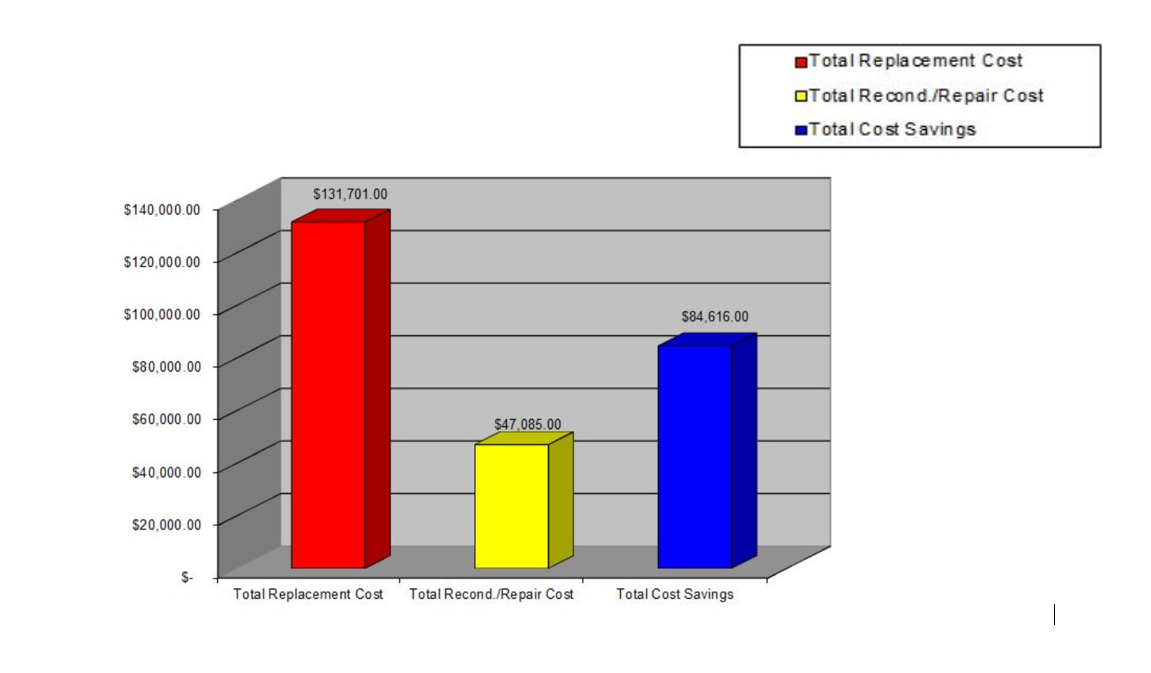

Carbide Tool takes cost savings one step further by documenting and providing cost savings reports upon request. These reports give our customers clear insights into how much they save by opting for tool repair, helping them make data-driven decisions for their businesses.

Cost Savings Report Analysis

Carbide Tool Services offers comprehensive cost savings analysis to help businesses make informed decisions about their tooling investments. Our detailed evaluations compare the cost of purchasing new tools versus repairing existing ones, offering real-time insights into the significant savings achieved through cutting tool repairs. See below for an example of the cost savings benefits of tool repairs and maintenance.

Tool Repair vs. Buying New: Which Is Right for You?

While there are cases where buying new tools is necessary, repair is often the more cost-effective and sustainable choice. With over 35 years of experience in carbide cutting tool repairs, our advanced repair processes restore all tools to original OEM specs. Our inspection team uses our catalog of pocket hardware to ensure precision in every pocket, every time. This means you get maximum value from your investment while reducing waste and lowering expenses.

Ready to start saving? Our team specializes in extending tool life and reducing replacement expenses, helping businesses maintain efficiency and profitability.

Contact Carbide Tool today to learn more about our tool repair process and request your cost savings report!